Robert Gcode unveiled a 3D printer few months ago that is roughly the size of a kitchen appliance – tiny enough to just place on a shelf if desired. Now the Quark has arrived, marking yet another attempt by Gcode to truly push the bounds of compact. This one measures only 100 millimeters on each side, making it small enough to fit in a pocket or balance on an open hand.

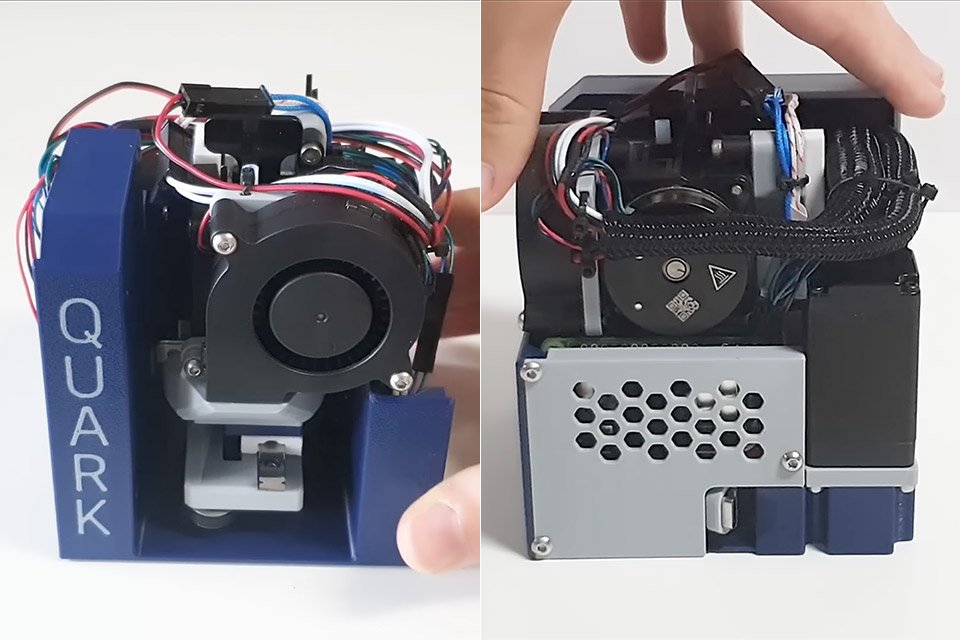

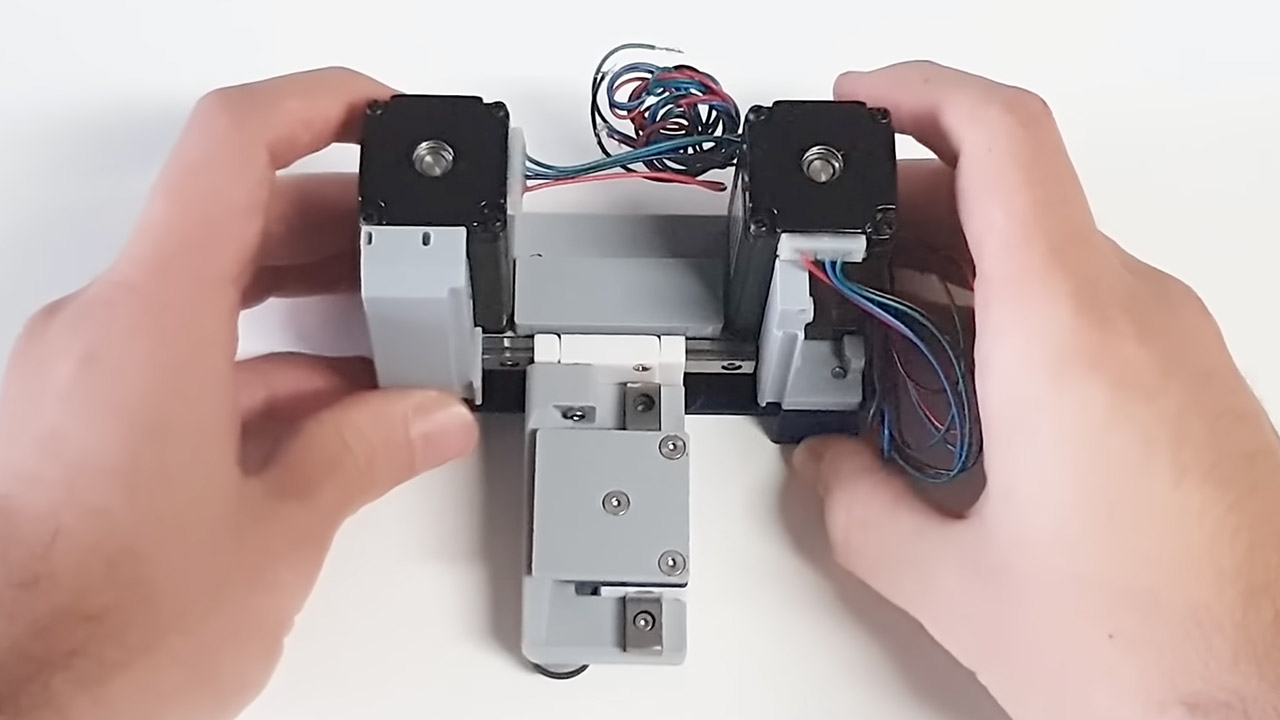

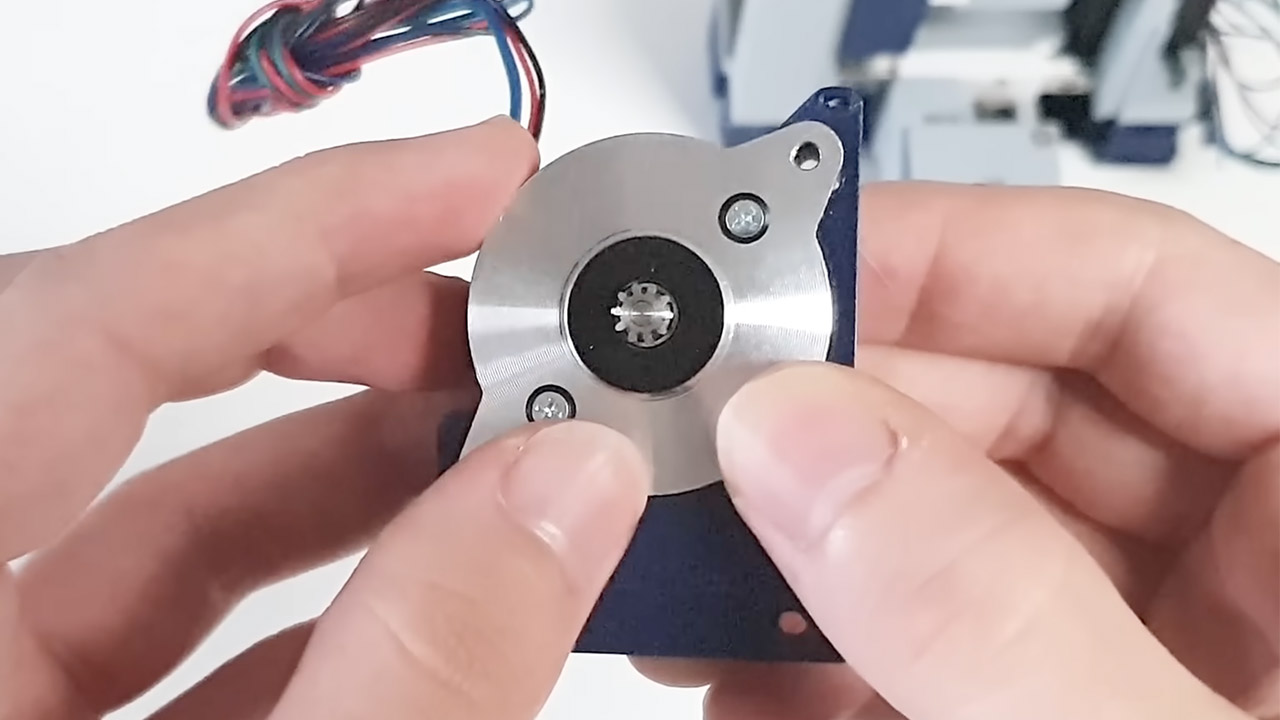

Every inch of space within the Quark is packed to the brim, with little room to spare. The frame, made layer by layer of plastic, ties everything together with a near-perfectionism that’s unsettling. Stepper motors handle the X and Y movements, taking up the majority of the inside area because Robert was working with the parts he had on hand. The Z axis is powered by a pancake motor, which does an excellent job of smoothly and consistently moving the print head up and down. The extruder works the same way, using a pancake design to push filament through a standard hot end—no fancy special pieces here, just the tried-and-true arrangement squeezed into some rather tight locations. Linear rails guide the motion; they have been reduced to fit but are otherwise identical to those used on larger rigs.

Sale

FLASHFORGE Adventurer 5M 3D Printer with Fully Auto Leveling, Max 600mm/s High Speed Printing, 280°C…

- One-Click Automatic Printing: Experience hassle-free 3D printing with the Adventurer 5M Series. Enjoy automatic bed leveling for flawless first…

- 12X Ultra Fast Printing: Featuring a CoreXY structure with 600mm/s travel speed and 20000mm/s² acceleration, the AD5M maximizes efficiency, reduces…

- Smart and Efficient Design: Quick 3-second nozzle changes, a high-flow 32mm³/s nozzle, and fast 35-second warm-up to 200°C deliver stable high-speed…

A Mellow Fly Micro 4 board is in charge, chosen for its small size and ability to fit between the motors and rails. This board is unique in that it fits a lot of functionality into a small footprint, leaving just enough space for a Raspberry Pi Zero. That tiny computer is running Klipper firmware, where slicing and sequencing is handled with the same confidence and composure as a full-sized machine.

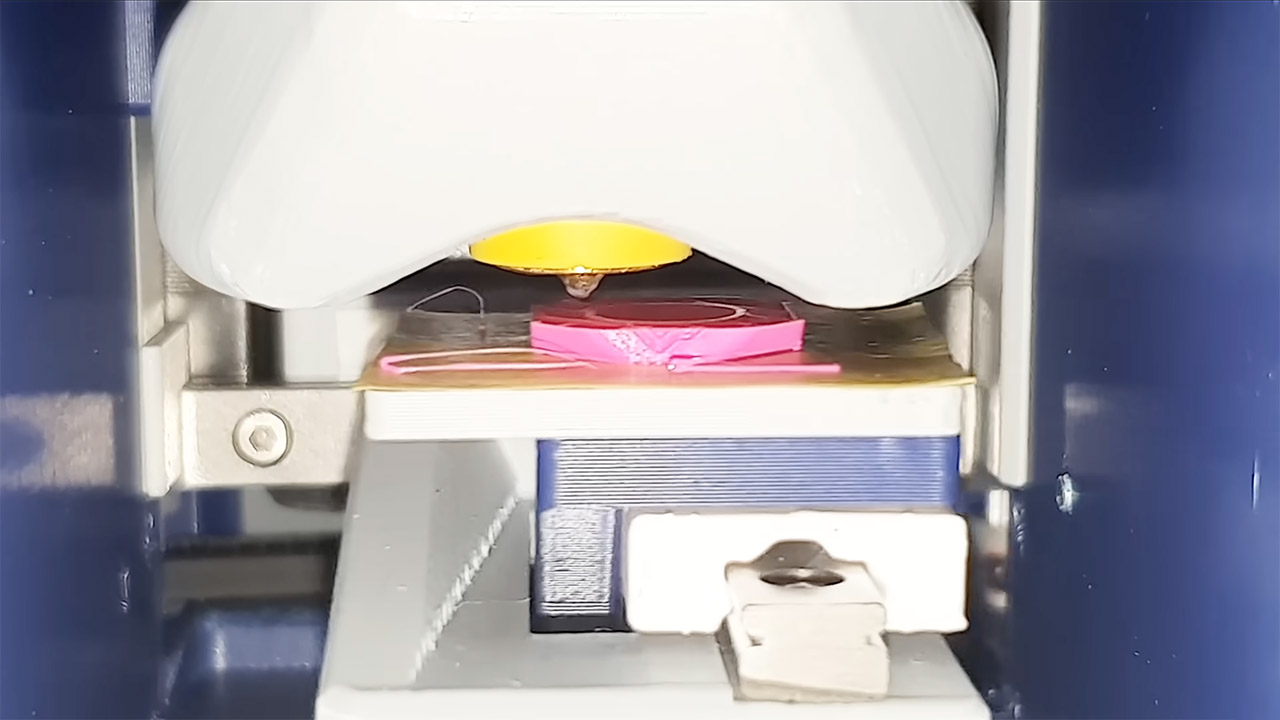

The scale of things at which the Quark prints gives you a good idea of just how restrictive Gcode is. The build area is a tiny cube, 24 millimeters in each direction – that’s smaller than the tip of your thumb. The prints show up as miniatures – a gear tooth, a little keychain charm, or even a thimble-sized vase are all good examples. As you feed in the filament, heat it up, and put down a new layer, the thing starts to take shape. Because you’ve got to keep the speeds pretty low to avoid losing any precision, the machine still works just fine.

Building the thing took several weeks, as he made the frame by printing out bits that fit together like a jigsaw puzzle and then welding the rails and motors one by one. Early on, testing showed up a bit of flex in the frame, so he epoxied in some scrap metal strips to stiffen it up. Wiring was a right pain – his big fingers were too big for the tiny apertures, so he had to come up with special hooks and just sit down and patiently reroute the lot. The first print was just a simple calibration cube, scaled down to fit, but it rolled off after a night or so of fiddling with the settings, its facets shining away in the workshop lights. Heat management was a bit of a worry because the enclosed chamber was retaining heat from the hot end. So, he carved some vents into the frame to let it air out while still keeping it rigid.

The Quark’s capabilities go way beyond just the print bed. It can level the surface itself using a manual crank, so you know the first layer’s going to be spot on. Bed heating kicks in instantly, warming up a tiny bit of aluminium plate, and you can just chuck some PLA or ABS at it without even thinking. Cooling’s done with a tiny fan that just whispers away, blowing air right onto the new layers. Klipper’s macros automate all the homing and startup nonsense, so it’s as simple as pressing a single button. Gcode has also toned down the acceleration curves to eliminate any vibrations, which means sacrificing a bit of speed for silence and sharpness.

[Source]